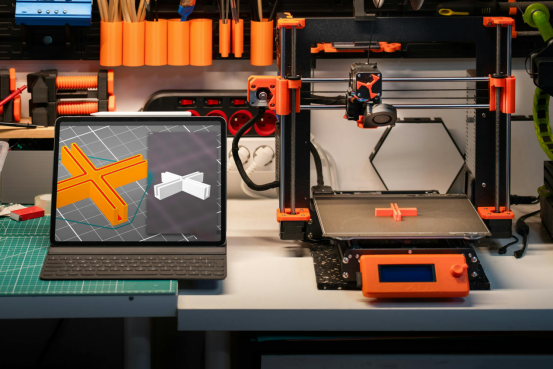

In science fiction movies, we often see such scenes: a mysterious machine flashes blue light, and complex parts appear layer by layer like magic. Today, such "magic" is becoming a reality - industrial 3D printers are quietly changing the world with subversive manufacturing methods.

Image Source:Pexels

1. Technical principle: the revolution from "carving" to "growth"

Traditional manufacturing is like "carving", using machine tools to cut materials and remove excess parts to get parts. Industrial 3D printing is like "growth", building objects by stacking materials layer by layer. This process is like building a castle with sand, but the accuracy can reach micron level.

Take laser selective melting (SLM) technology as an example, it is like "metal baking". The computer cuts the three-dimensional model into thin slices, and the laser beam accurately scans the metal powder bed to melt the powder in a specific area. After one layer is solidified, the workbench descends and the powder is re-applied, and the cycle continues until the part "grows" is completed. This technology can produce complex structures that are difficult to achieve with traditional processes, such as honeycomb lattices and conformal cooling channels.

Electron beam melting (EBM) technology is more like "space welding". In a vacuum environment, a high-speed electron beam melts the metal powder instantly to form a dense metallurgical bond. This technology is particularly suitable for difficult-to-process materials such as titanium alloys and has been used to manufacture aircraft engine brackets.

2. Application areas: "magic" from heaven to earth

Industrial 3D printers are breaking through the limitations of prototype manufacturing and moving towards large-scale production. In the aerospace field, it helps aircraft engine fuel nozzles to integrate multiple parts, reduce weight and extend life. In the medical field, it is a "customization expert" that prints hip implants for patients through CT data to achieve a perfect match with bones. In the dental field, it prints tens of millions of invisible braces every year to shorten the correction cycle.

In the automotive industry, industrial 3D printers are also very useful, used to produce aluminum alloy brackets for sports cars, reducing weight and improving performance.

3. Technological frontier: "double-winged" materials and efficiency

In the field of materials, new alloys and composite materials continue to emerge, making the performance of 3D printed parts surpass traditional manufactured parts. In terms of efficiency improvement, technologies such as multi-laser synchronous scanning and modular design have greatly increased printing speed and equipment utilization.

4. Industrial structure: China's strength in global competition

The global industrial 3D printer market presents a "three-legged" pattern: European and American companies occupy the high-end market, Japan leads in the field of materials, and China breaks through with a complete industrial chain. Companies such as Polylite and Farsoon High-Tech have mastered core technologies such as SLM and EBM, and their equipment has been exported to more than 30 countries. In the field of metal 3D printing, the installed capacity of Chinese companies accounts for 15% of the global market, an increase of 8 times compared with 2015.

5. Future Outlook: The transition from "manufacturing" to "intelligent manufacturing"

Digital twin technology, blockchain technology, etc. are deeply integrated with 3D printing to achieve full-process digitalization and full life cycle traceability of design, production, and testing.

What's more exciting is that when nano-level precision meets biological ink, 3D printing is opening a new era of "biomanufacturing". Scientists have been able to print liver tissue with a vascular network, providing new possibilities for organ transplantation. In the field of construction, 3D printers can even "print" an entire office building, and the wall is embedded with optical fibers to achieve intelligent temperature control.

Industrial 3D printers, a magic box once regarded as "future technology", are changing the manufacturing industry at an astonishing speed. From space exploration to life continuation, from microscopic cells to macroscopic buildings, they continue to break through physical limits and turn creativity into reality. In this additive manufacturing revolution, we are witnessing the transformation of the manufacturing industry from a "follower" to a "parallel" and even a "leader", writing an industrial legend of this era.

- pre:Supply of Chinese Metal Machinery in Multiple Industries and Future Trends

- next:Intelligent New Force in Trillion-Dollar Catering Market

Please click to consult us immediately or call the hotline: 4006-979-616We will solve the problems in your heart in detail。Online consultation

Online Service

Online Service