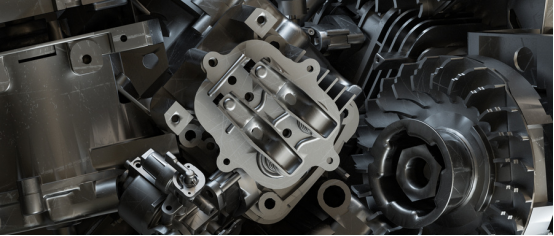

In the modern industrial system, metal machinery occupies a crucial position. It is widely applied in multiple industries, providing indispensable support for the development of various sectors. From automotive manufacturing to aerospace, from construction to machining, metal machinery is omnipresent. Its supply situation is closely linked to market demand and profoundly influences the future direction of the industry.

Image Source:699pic

Metal machinery also plays an important role in the construction process. Lifting equipment such as cranes is a common sight at construction sites, used for hoisting building materials, erecting building structures and other operations. Cranes of different types and lifting capacities meet the needs of various construction projects, from ordinary residential construction to super high - rise building construction. In addition, metal processing machinery such as steel bar bending machines and cutting machines are used to process steel bars for construction, ensuring that the steel bars play a stable supporting role in the building structure. In the field of architectural decoration, metal cutting and forming equipment is used to process various metal decorative materials, such as the production of aluminum alloy doors and windows, adding beauty and practicality to buildings.

With the continuous miniaturization and refinement of electronic information products, extremely high requirements are placed on the precision and miniaturization processing capabilities of metal machinery. In the semiconductor manufacturing process, high - precision metal etching equipment is used to etch extremely fine circuit patterns on silicon wafers, with an accuracy that can reach the nanometer level. In the manufacturing of electronic components, miniature metal stamping equipment is used to produce tiny components such as mobile phone SIM card slots and electronic connectors. These devices are required to have high speed, high precision and high stability to meet the mass production needs of electronic products.

In recent years, the scale of China's metal machinery market has continued to expand. On the one hand, the rapid development of domestic industries has driven strong demand for metal machinery; on the other hand, with the improvement of China's manufacturing technology level, domestic metal machinery has continuously improved in performance and quality, gradually achieving import substitution. In terms of the market competitive landscape, there are a large number of metal machinery enterprises in China, and market competition is fierce. Some leading enterprises have gradually emerged in the high - end product field through continuous technological research and development and innovation, competing with international well - known brands. However, overall, there is still a certain gap between China's metal machinery industry and the international advanced level in high - end products, and some high - end equipment still relies on imports. At the same time, there are many small and medium - sized enterprises in the industry, and the problem of product homogeneity is relatively serious. Market competition mainly focuses on price, which to a certain extent affects the overall profit level and technological innovation ability of the industry.

Intelligence will be an important development direction for metal machinery in the future. With the continuous development of technologies such as artificial intelligence and the Internet of Things, metal machinery will evolve towards intelligence and automation. Intelligent machine tools can use sensors to monitor various parameters during the processing process in real - time and automatically adjust the processing technology according to preset programs, realizing the optimization and adaptive control of the processing process, improving processing accuracy and efficiency, and reducing the reject rate. At the same time, intelligent metal machinery can also achieve remote monitoring and fault diagnosis. Through the Internet of Things technology, equipment operation data is transmitted to the cloud, allowing technicians to monitor and maintain the equipment anytime and anywhere, reducing equipment downtime and improving production efficiency.

Against the backdrop of increasingly stringent environmental protection requirements, the green transformation of metal machinery is imperative. On the one hand, metal machinery manufacturing enterprises will pay more attention to the energy - saving design of products. By optimizing equipment structures and adopting high - efficiency energy - saving drive systems, the energy consumption during equipment operation can be reduced. On the other hand, during the metal processing process, green processing technologies such as dry cutting and cryogenic cutting will be promoted to reduce the use of pollutants such as cutting fluids and minimize the impact on the environment. At the same time, efforts will be made to strengthen the recycling and reuse of metal processing waste, improve resource utilization, and achieve the sustainable development of the metal machinery industry.

In order to meet the demand of domestic high - end manufacturing for metal machinery and achieve import substitution, China's metal machinery industry will increase investment in the research and development of high - end products in the future. In the fields of high - precision and high - performance metal cutting machine tools, forming machine tools, and special processing equipment, key core technologies will be broken through through technological innovation and industry - university - research cooperation, improving the technical level and quality stability of domestic metal machinery. For example, in high - end products such as five - axis machining centers and ultra - precision machining equipment, efforts will be made to continuously narrow the gap with the international advanced level and enhance the competitiveness of Chinese metal machinery in the international market.

The Chinese metal machinery industry plays an important role in the supply of multiple industries. Although the current market competitive landscape is complex, driven by future trends such as intelligence, greening, and high - end development, it is expected to achieve higher - quality development and provide stronger support for the transformation and upgrading of China's manufacturing industry.

Please click to consult us immediately or call the hotline: 4006-979-616We will solve the problems in your heart in detail。Online consultation

Online Service

Online Service