Driven by the wave of intelligent manufacturing, the in-depth integration of 5G and Internet technologies is bringing disruptive changes to the packaging equipment industry. With its core advantages of high bandwidth, low latency, and wide connectivity, 5G+Internet technology has broken the spatial constraints and data barriers of traditional packaging production, promoting the upgrading of packaging equipment from single-machine automation to full-link intelligence. The application scenarios for implementation are constantly enriched, making it a key driving force for the industry to improve quality and efficiency and transform and upgrade.

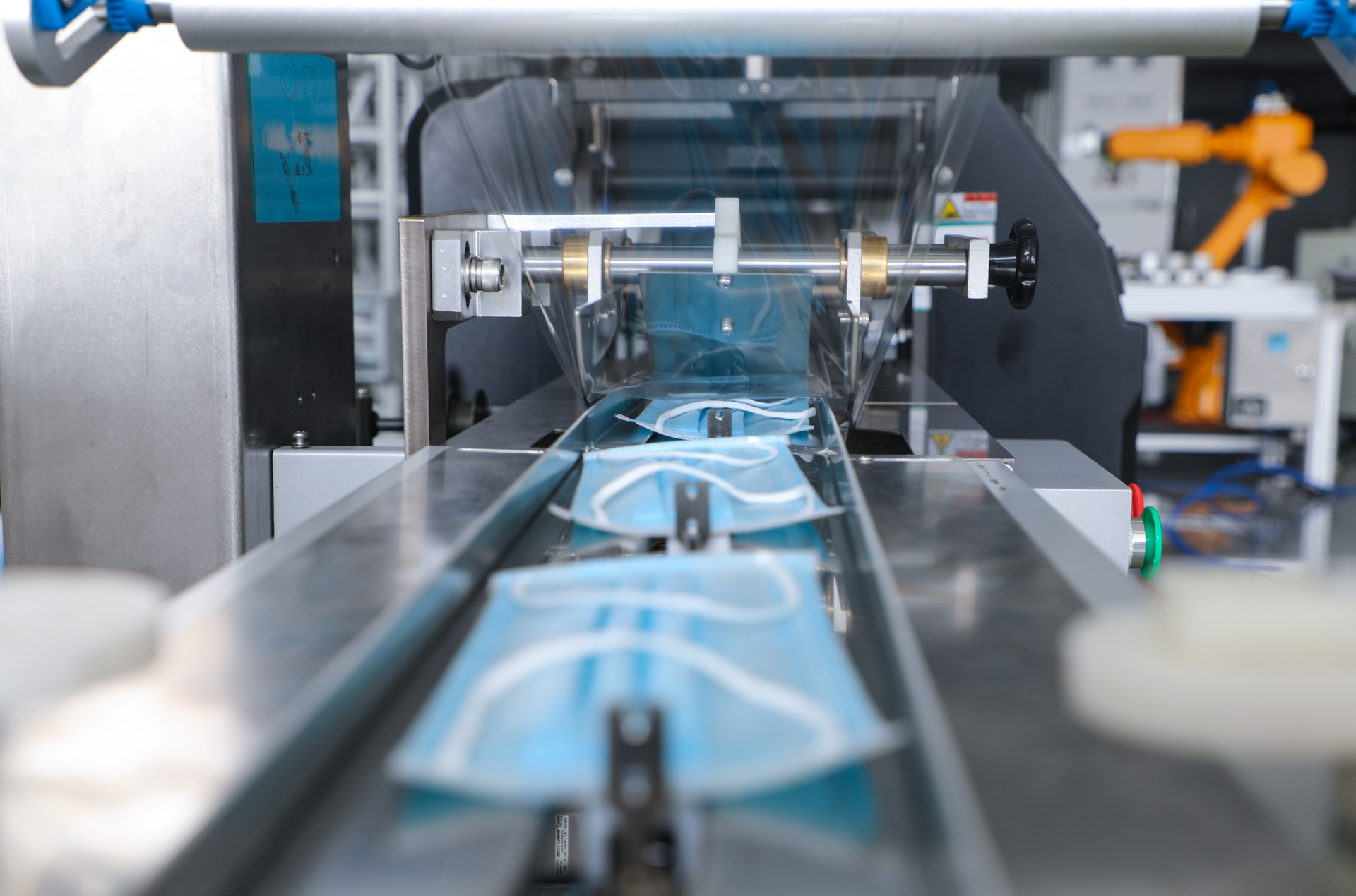

Image Source:699pic.com

The comprehensive construction of a remote operation and maintenance system is one of the core application scenarios for the implementation of 5G+Internet in the packaging equipment field. In traditional packaging production, operation and maintenance work such as equipment commissioning and fault diagnosis requires on-site operations by engineers, which not only results in delayed responses but also incurs high travel costs, seriously affecting production continuity. Relying on the private virtual network built by 5G, remote access and control of packaging equipment distributed in various regions can be realized without the deployment of high-cost public IPs or dedicated lines. Through the remote platform, engineers can real-time access the equipment controller and operation interface to complete core operation and maintenance operations such as parameter adjustment, program issuance, and fault diagnosis, greatly shortening the response time, reducing operation and maintenance costs, and effectively improving equipment utilization rate. Especially for equipment deployed across regions and even overseas, the 5G global intelligent link can real-time detect link quality and intelligently select the optimal access node, ensuring the stability and smoothness of remote operations and solving the common problems of bandwidth bottlenecks and excessive latency in traditional remote solutions.

The data connection and intelligent management and control of the entire production process are another important breakthrough in the implementation of 5G+Internet. The packaging production process involves various equipment such as filling machines, labeling machines, and palletizers. In the traditional mode, the data of each equipment is scattered, relying on manual recording and statistics, which is prone to errors and poor timeliness, making it difficult to achieve refined management. Through the combination of 5G technology and industrial gateways, key data such as the operating status, temperature, pressure, and energy consumption of packaging equipment can be real-time collected and uploaded to the cloud platform via the Internet, realizing centralized management and visual presentation of production data. Managers can fully grasp the operation status of the production line through terminal equipment, timely detect parameter abnormalities and quickly correct them, breaking the information gap between production and management. At the same time, based on the analysis and mining of massive data, it can also provide accurate support for the optimization of production processes and cost accounting, realizing digital management and control of the entire process from raw material warehousing to finished product outbound, shortening the cost accounting from the traditional daily and weekly level to real-time completion, and greatly improving decision-making efficiency.

The improvement of multi-equipment collaboration and flexible production capabilities further highlights the technical value of 5G+Internet. In modern packaging workshops, 5G networks have realized the wireless and flexible access of various production factors such as packaging equipment, AGV robots, and intelligent warehouses, building an efficient and collaborative production system through the Internet of Things platform. With the help of 5G high-speed transmission capabilities, the robot scheduling system can simultaneously dispatch a large number of equipment to complete operations such as raw material transfer, semi-finished product turnover, and finished product warehousing, with the docking accuracy controlled at the millimeter level, replacing a lot of manual labor, and improving the efficiency and safety of logistics circulation. This collaborative capability not only optimizes the production cycle of a single workshop but also promotes the flexible upgrading of packaging production lines, which can quickly adapt to the production needs of small batches and multiple varieties. Through information sharing and linkage adjustment between equipment, the dynamic optimization of the production process is realized to respond to the diverse changes in market orders.

In the process of implementation, the industry has gradually overcome a series of technical difficulties. In response to the differences in control systems and communication protocols of packaging equipment of different brands, the 5G+Internet solution has realized the unified access and management of heterogeneous equipment by compatible with multiple industrial protocols; facing data security challenges, measures such as building a private virtual network, full-process encrypted data transmission, and refined permission management have effectively prevented the risks of data leakage and malicious attacks; the combination of edge computing and 5G has further reduced network latency and ensured the real-time control accuracy of key links in packaging production.

With the continuous maturity of technology, the application of 5G+Internet in the packaging equipment field is extending from core production links to the entire industrial chain, and advanced application scenarios such as digital twins and predictive maintenance are gradually being implemented. In the future, with the improvement of industry standardization and the reduction of technical costs, 5G+Internet will be popularized in more small and medium-sized packaging enterprises, promoting the entire industry to develop in a more intelligent, efficient, and green direction, and injecting continuous impetus into the high-quality development of the packaging industry.

- pre:The opportunities and challenges for South Korean semiconductor equipment exports in 2025

- next:Global Supply Chain Resilience Breakthrough in 2025

Please click to consult us immediately or call the hotline: 4006-979-616We will solve the problems in your heart in detail。Online consultation

Online Service

Online Service