In the modern industrial system, cutting machines are core equipment in the material processing link. Their function is to process various raw materials such as metal, wood, plastic, and stone into components of specific shapes and sizes that meet production requirements. The expansion of their application scope and technological iteration also simultaneously drives changes in production methods across various industrial fields, making them a key link connecting raw material supply and end-product manufacturing.

Image Source:699pic.com

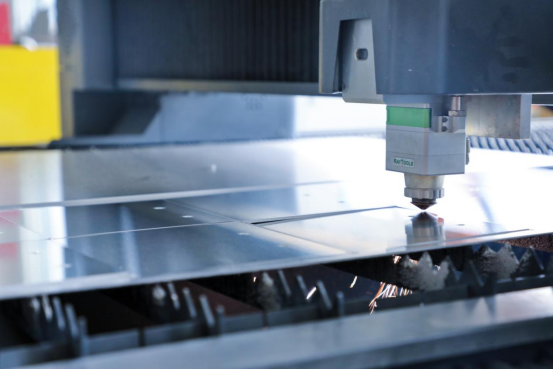

Classified by cutting principle, cutting machines can be divided into three major categories: thermal cutting, mechanical cutting, and electrical discharge machining (EDM) cutting. Each category has formed distinctive technical advantages targeting different material properties and processing needs. Thermal cutting includes three main forms: flame cutting, laser cutting, and plasma cutting.During the processing, the heat-affected zone is small, the cutting precision is high, the kerf width is narrow, and the surface roughness of the processed components is low, requiring no additional secondary grinding. This technology has strong adaptability to the processing of non-ferrous metals such as stainless steel, aluminum, and copper, with a cutting speed significantly higher than that of traditional flame cutting, and can process thicker plates.

Mechanical cutting is typically represented by waterjet cutting. The core of this technology is to pressurize water to hundreds of megapascals through a high-pressure water pump to form a high-speed water jet; if abrasives such as garnet are added to the water jet, it can also cut hard and brittle materials such as ceramics and stone. This non-contact cutting method does not cause thermal deformation and does not change the physical and chemical properties of the material, so it is widely used in scenarios where high requirements are placed on material performance. Wire electrical discharge machining (WEDM) realizes cutting by means of pulse discharge between the electrode wire and the workpiece, which generates high temperatures to melt or vaporize the local surface of the workpiece, while the movement of the electrode wire forms the kerf. This technology is particularly suitable for the precision processing of high-hardness metal materials such as die steel and cemented carbide, and plays an irreplaceable role in fields such as mold manufacturing.

Regardless of the cutting principle adopted, the core structural design of cutting machines revolves around three core requirements: "precision drive, stable control, and efficient cooling". The control system is like the "brain" of the equipment, using numerical control technology to achieve precise planning of the cutting path; modern equipment further integrates intelligent algorithms, which can automatically adjust cutting parameters.

The application of cutting machines has penetrated into all aspects of industrial production, forming an application pattern of "full material coverage and multi-scenario adaptation". In the field of metal processing, laser cutting machines can process various plates such as stainless steel, carbon steel, and titanium alloy, and can not only cut precision parts required in aerospace, but also meet the processing needs of body panels in automotive manufacturing. Plasma cutting is mostly used in medium and thick plate metal processing scenarios such as shipbuilding and steel structure processing. Waterjet cutting plays an important role in stone inlay and glass processing in the architectural decoration field, as well as ceramic substrate cutting in the electronics industry. In addition, in some special fields, such as frozen meat cutting in food processing and multi-layer material cutting in composite material processing, specialized cutting machines can also meet specific processing needs.

With the transformation of the manufacturing industry towards intelligentization, refinement, and green development, cutting machine technology is showing three major development trends. In terms of intelligentization, equipment is gradually integrating machine vision systems and artificial intelligence algorithms, which can automatically identify material types, sizes, and surface conditions, and then automatically match the optimal cutting parameters; some equipment also supports remote monitoring and fault diagnosis, and can predict equipment failures in advance through data analysis to reduce downtime. In the development of high-precisionization, the kerf width of laser cutting can be controlled within 0.1 millimeters, and some high-end equipment has achieved high-precision tracking of complex curves by adopting dual-drive synchronous transmission and dynamic focusing technology; the processing precision of wire electrical discharge machining can also reach the micron level, meeting the processing needs of precision instruments and semiconductor devices. In terms of green development, new cutting machines reduce dust and smoke emissions generated during cutting by optimizing structural design and adopting closed cutting chambers and high-efficiency filtration systems; at the same time, the application of energy-saving power components (such as high-efficiency lasers and energy-saving motors) reduces equipment energy consumption, in line with the concept of low-carbon production.

From traditional mechanical cutting equipment to modern intelligent cutting systems, the development of cutting machines has always focused on the core goals of "improving processing efficiency, ensuring processing precision, and reducing processing costs". In the future, with the further development of materials science and intelligent control technology, cutting machines will achieve a wider range of material adaptation capabilities, more precise processing control levels, and more environmentally friendly production methods, continuing to provide technical support for the high-quality development of the manufacturing industry.

- pre:Analysis of the Export Situation of Chinese Construction Machinery

- next:The Convenient Use and Scenario Value of Outdoor Automatic Robots

Please click to consult us immediately or call the hotline: 4006-979-616We will solve the problems in your heart in detail。Online consultation

Online Service

Online Service