In fields such as industrial production, scientific research experiments, and engineering construction, machine electronics equipment serves as a core production factor. The scientific nature of its selection directly affects production efficiency, product quality, and operational costs. Machine electronics equipment integrates multiple characteristics such as mechanical structure, electronic control, and automation technology, with a wide range of types and rapid technological iteration. How to select equipment that meets needs among numerous options requires establishing a systematic selection framework that balances technical performance, actual scenarios, and long-term value.

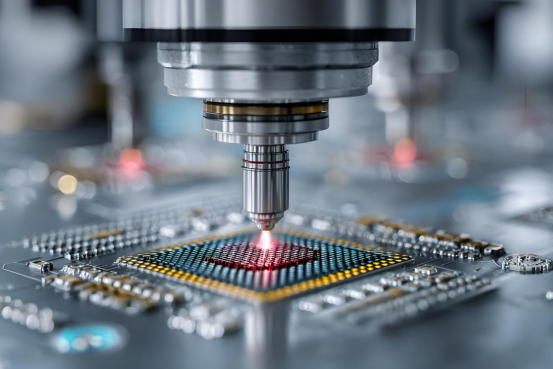

Image Source:699pic

I. Disassembling Technical Parameters

The technical parameters of machine electronics equipment are an intuitive reflection of performance. It is necessary to focus on disassembling core indicators based on needs to avoid being distracted by redundant parameters. In terms of mechanical structure, attention should be paid to basic parameters such as load capacity, operating speed, and transmission accuracy. Energy consumption and energy efficiency ratio are key to long-term operating costs. It is necessary to compare the rated power, standby energy consumption of the equipment, and energy consumption per unit output. Especially in high-energy-consuming industries, differences in energy efficiency may lead to annual cost differences of hundreds of thousands of yuan. In addition, the safety protection level of the equipment (such as IP rating, mechanical protection design) must comply with industry standards to avoid affecting production continuity due to safety hazards.

II. Evaluating Equipment Reliability and Durability

The reliability of equipment is directly related to the risk of production interruption and maintenance costs, which is an easily overlooked but crucial link in selection. Evaluation should be conducted from three aspects: quality of core components, rationality of structural design, and fault early warning capability. The brand and model of core components such as motors, bearings, and controllers are the basis of reliability. Structural design needs to examine stress distribution, heat dissipation layout, and the convenience of replacing vulnerable parts. For example, whether key connections of the equipment adopt reinforced design, and whether the layout of cooling fans can avoid local overheating. Fault early warning capability reflects the intelligence level of the equipment. Equipment with vibration monitoring, temperature alarm, and operating data recording functions can detect potential faults in advance, reducing the probability of sudden shutdowns. At the same time, it is necessary to refer to quantitative indicators such as the mean time between failures (MTBF) and mean time to repair (MTTR) of the equipment, combined with industry cases and user feedback, to comprehensively judge the long-term stability of the equipment.

III. Adapting to Scenarios and Expandability

Equipment selection should avoid the "one-time purchase" mindset, not only adapting to current production needs but also reserving space for future upgrades. Scenario adaptability is reflected in whether the equipment size and layout conform to workshop planning. For example, small laboratories need to choose compact equipment, while large production lines need to consider the modular combination capability of the equipment. Human-computer interaction design should conform to operating habits. Whether the operation interface of complex equipment is intuitive and whether training costs are controllable will affect actual use efficiency. In terms of expandability, attention should be paid to the interface compatibility and upgrade potential of the equipment, such as whether it supports adding sensors, expanding communication protocols (such as Modbus, Profinet), and accessing the factory Internet of Things system to achieve data intercommunication. For fields with rapid technological iteration (such as 3C manufacturing, intelligent equipment), the software upgrade capability and hardware modular design of the equipment are particularly important, which can extend the technical life cycle of the equipment and avoid being eliminated in the short term.

IV. Comprehensive Cost Accounting

Cost evaluation for equipment selection should cover the entire life cycle, not just the initial purchase price. Procurement costs include direct expenditures such as equipment price, transportation and installation fees, and commissioning and training fees. It is necessary to compare the quotation composition of different suppliers to avoid hidden costs. Operating costs involve long-term expenditures such as energy consumption, consumable replacement, and daily maintenance. For example, the price of special consumables for high-precision equipment and the replacement frequency of vulnerable parts will significantly affect annual operating costs. Shutdown losses are hidden but critical cost items. Equipment with low reliability may cause production line shutdowns due to frequent failures, and the loss calculated by daily production capacity may far exceed the equipment price difference. In addition, the residual value and depreciation rate of the equipment should be considered. High-quality equipment can still be transferred through the second-hand market after several years of use to recover part of the value, while technologically backward or frequently faulty equipment may face the dilemma of being "worthless". Only through full-life-cycle cost accounting can the most cost-effective equipment be selected.

V. Investigating Supplier Strength and Services

The strength and service capability of equipment suppliers directly affect the user experience and problem-solving efficiency after selection. The quality of training services determines whether the equipment can be put into production quickly. High-quality suppliers will provide systematic operation training, maintenance training, and supporting detailed operation manuals and video tutorials. In addition, the supplier's reputation and user cases are valuable references. Peer research and online reviews can be used to understand the actual use feedback and service fulfillment capabilities of their equipment.

Machine electronics equipment selection is a comprehensive decision involving technology, scenarios, costs, and services, requiring the establishment of a thinking framework of "demand orientation, performance matching, and full-cycle consideration". Starting from accurately defining needs, through technical parameter disassembly, reliability evaluation, scenario adaptability analysis, combined with full-life-cycle cost accounting and supplier investigation, it is possible to select equipment that not only meets current production needs but also has long-term value. In the context of intelligent manufacturing and industrial upgrading, equipment selection also needs to integrate the concepts of intelligence and greenization to lay an equipment foundation for the sustainable development of enterprises.

- pre:Characteristics and advantages of centralized procurement of machinery and equipment

- next:Sewage treatment equipment, a powerful assistant for sewage purification

Please click to consult us immediately or call the hotline: 4006-979-616We will solve the problems in your heart in detail。Online consultation

Online Service

Online Service